Hunter Wall PAnels

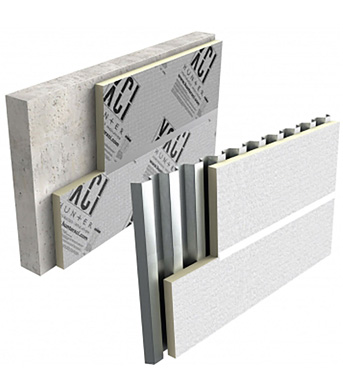

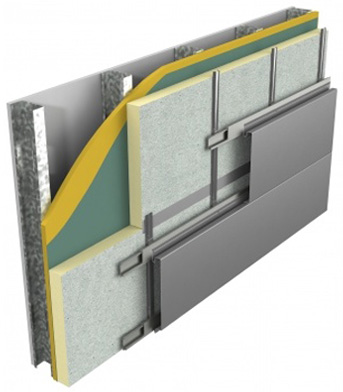

Our most popular Hunter XCI product offerings include:

XCI 286

Xci 286 is an energy-efficient rigid foam insulation composed of a polyisocyanurate foam core manufactured on-line to glass fiber reinforced foil facers. It can be used in new construction, or used for interior retrofit within existing buildings. Xci 286 is designed for exposed interior wall or ceiling use in a variety of applications, including metal buildings.

- Polyiso offers increased R-Value per inch vs. mineral fiber, XPS or EPS options

- Passed NFPA 286 Corner Burn Test for walls or ceilings only, with or without joint treatment, allowing product to be left exposed on interior application without a thermal barrier up to 3.5″ thick

- Passed UL 1715 with up to 8″ for ceilings only

- Flame spread of 25 per ASTM E 84

- Both sides reinforced foil, one side reflective, one side white, either side may be left exposed

Xci 286 Submittal Doc

Xci 286 Spec Sheet

Xci 286 Case Study

Xci Install Guide (Part 1 – Over An Air Barrier)

Xci Install Guide (Part 2 – Used As An Air Barrier)

XCI CG

Xci CG is a high-thermal rigid insulation panel composed of a closed cell polyisocyanurate foam core manufactured on-line to premium performance coated glass facers on both sides. It is designed for use in commercial wall applications to provide continuous insulation within the building envelope. Polyiso offers increased R-Value per inch vs. mineral fiber, XPS or EPS options Designed for use in continuous insulation to assist in meeting the most current ASHRAE 90.1, IECC, IBC and IRC standards

Xci CG Submittal Doc

Xci CG Spec Sheet

Xci CG Case Study

Xci Install Guide (Part 1 – Over An Air Barrier)

Xci Install Guide (Part 2 – Used As An Air Barrier)

XCI Foil (Class A)

Xci Foil (Class A) is an exterior wall insulation panel composed of a Class A rigid polyisocyanurate foam core manufactured on-line to reinforced foil facers on both sides. It is designed for use in commercial wall applications to provide continuous insulation within the building envelope.

- Polyiso offers increased R-Value per inch vs. mineral fiber, XPS or EPS options

- Designed for use in continuous insulation to assist in meeting the most current ASHRAE 90.1, IECC, IBC and IRC standards

- Can be installed directly on steel studs in a variety of wall assemblies without the need for gypsum sheathing

- Flame spread of 25 per ASTM E 84

- Provides R-Values from 6.3 to 22.0 in a single layer

- Superior fire performance, durability and dimensional stability

- Exterior facer treated with non-reflective coating

Xci Foil (Class A) Submittal Doc

Xci Foil (Class A) Spec Sheet

Xci Foil (Class A) Case Study

Xci Install Guide (Part 1 – Over An Air Barrier)

Xci Install Guide (Part 2 – Used As An Air Barrier)

XCI Foil

Xci Foil is a high thermal, rigid building insulation composed of a closed cell polyisocyanurate foam core bonded on-line during the manufacturing process to an impermeable foil facing material. It is designed for use in commercial cavity wall applications to provide continuous insulation within the building envelope.

- Designed for use in continuous insulation to assist in meeting the most current ASHRAE 90.1, IECC, IBC and IRC standards.

- Lightweight yet durable, easy to handle. Cuts with a knife or saw.

Xci Foil Submittal Doc

Xci Foil Spec Sheet

Xci Foil Case Study

Xci Install Guide (Part 1 – Over An Air Barrier)

Xci Install Guide (Part 2 – Used As An Air Barrier)

For NFPA 286 compliance information, email us: info@therm-all.com.